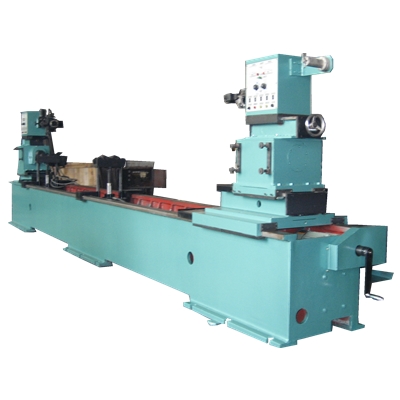

The machine is such a facility used in building construction to weld circumferential seams of rack members, which is composed of two YD—500KR CO2-shielded welding units. The machine can complete welding at both ends at a time. It’s applicable to workpieces with a diameter of φ42~φ219mm and with a length of 400~5000mm.The machine is equipped with an automatic gun holder and a swing mechanism, which can perform welding in two layers automatically for deep and wide seams, i.e. the first layer is for backing, when completed, the gun will be lifted automatically to proceed to the second layer (facing) by way of swinging. Except loading and unloading of workpieces, all processes can be finished automatically, featuring easy adjustment, high reliability and degree of automation. The machine is controlled by the programmable logic controller, hence improving the productivity and quality of welding.

Key Specifications and Technical Parameters

Length of welded workpieces -------------------------------400~5000mm

Dia. of welded workpieces --------------------------------φ42~φ219mm

Speed of welding ---------------------------------------------------------0~2.5rpm

Stroke of clamping cylinder -------------------------------------------200m

Pressure Adjustment of hydraulic system --------------1.5~3.5Mpa